Northpoint is committed to providing high quality coatings that ensure anti-corrosion protection and a lasting finish. We pride ourselves on our coating solutions fulfilling both practical and decorative purposes.

To improve the overall finish of our projects, we offer a Shot Blasting service to prepare the metal part to be coated. Preparation involves the removal of any mill scale or existing coatings from the part and ensuring that the surface is smooth and clean so that our Powder Coating solution applies evenly and will not chip or fade.

What is Shot Blasting?

Shot Blasting is a form of abrasive cleaning which is primarily used for surface protection and preparation for processing of the part such as painting or coating. The process involves propelling abrasive materials at the surface of the metal part at extremely high pressure.

Shot Blasting Benefits

Shot Blasting cleans, strengthens, and polishes the metal. It allows any weaknesses to be identified and rectified by the engineer before coating. It also removes any grease, dust and rust.

A smooth finish is not the only benefit of our shot blasting methods; after the metal part has been cleaned, the engineer can, at this point, also identify any structural issues such as compromised weld joints and corrosion. These issues can then be addressed to provide reinforced reliability of your part!

Shot blasting a metal part or pipe is both cost effective and environmentally friendly, in that it allows the part to be recoated and repurposed.

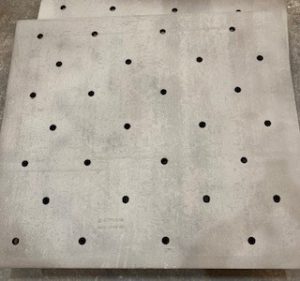

A before and after visual of floor plates for the Intel factory in Dublin, Ireland. Following the shot blasting treatment, the plates will be recoated using Fusion Bonded Epoxy (FBE) coating, providing a one-stop solution for the refurbishment of parts.

Northpoint Shot Blasting Services

Shot Blasting is an essential part of the service here at Northpoint which will save our clients money both in the short term and in the long term. Our Shot Blasting capabilities also prevent the client from having to purchase new parts to be coated, as we can restore the metal to its original state and essentially ‘start again’. Due to the anti-corrosion, anti-vandal, and weatherproof qualities to our coating solutions, we can guarantee a 10-year life expectancy before the need for recoating.

Northpoint offers two types of Shot Blasting dependent on suitability to the project at hand:

- Hanger Type Shot Blasting

Hanger type shot blasting is a semi-automated process, where descaling and reconditioning of parts is required. This process is perfect for smaller parts which can be loaded into the Shot Blasting machine.

- Blast Booth Shot Blasting

The Blast Booth is used before coatings are applied to large water carrying pipes. This technique is manual and involves the operator using a handheld device to shoot the abrasive materials at the affected areas on the part.

Technical Information

Northpoint can provide shot blasting of a commercial grade finish, meeting the ISO 8501-1 Sa 2.5 or ISO 8501-1 Sa 3 standards.

Contact Us today for a quotation of your project!

Northpoint Ltd is a UK market leader in Coating solutions for both decorative and functional purposes. Northpoint provides an anti-corrosion pipe coating service; the powder coatings used are Drinking Water Inspectorate (DWI) approved. Our fence coating services consist of Architectural Powder Coatings available in a variety of colours. These can be applied to galvanised steel and are perfect for coating outdoor furniture. Our coating formulas serve both functional and decorative purposes and, in most cases, come with a 10-year life span guarantee, saving you money and time. Find out more: https://www.northpoint.ltd.uk/

Recent Comments