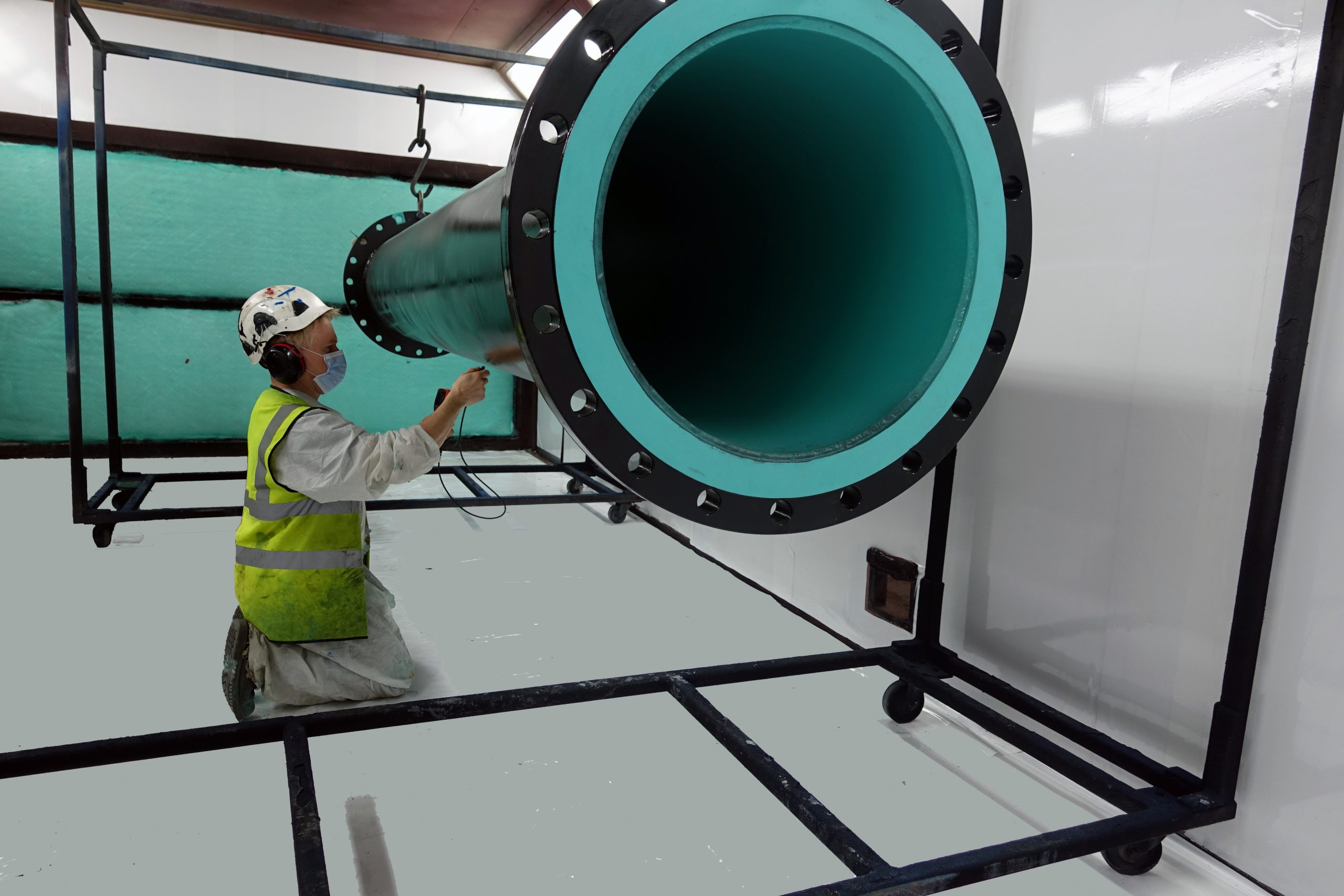

Northpoint provides wet paint services to a full range of sectors, from nuclear, oil and gas, and renewables; to aerospace, water treatment and military. Our dedicated wet paint facility has a state-of-the-art SprayBake Booth (spray booth LEV with oven capabilities) and a range of application equipment including Graco Merkur 45:1 air assisted airless, Graco XTreme 60:1 airless & Graco XM 2k Plural. The wet paint booth can accommodate parts up to 7m (L) x 4m (W) x 2.4m (H).

Specialist training has been undertaken by key team members to ensure that the requirements of SSPC Train the Painter Scheme and Coatings Inspectors qualified to NACE I, II & III as well as ICorr L2 are met.

The dedicated wet paint booth is set up for the professional application of:

- Single layer

- Multi-layer

- 100% Volume solids

- Phenolic paints

- DWI approved systems

Northpoint has a wealth of experience, with over 30 years experience in the application of corrosion protection coatings. The wet paint systems can be tailored to meet the demands of NORSOK M-501 or other customer specific requirements such as Glass-Flake paint, High-Zinc Solids primers or Novolac Epoxies.

Whatever your requirement, Northpoint can provide a solution that will meet specific standards and finishes. Contact us today for a quotation.